The Association for Manufacturing Technology (AMT) issued its latest monthly report for U.S. manufacturing technology orders on Sept. 12, showing a deceleration in July on both a month-to-month and year-over-year basis.

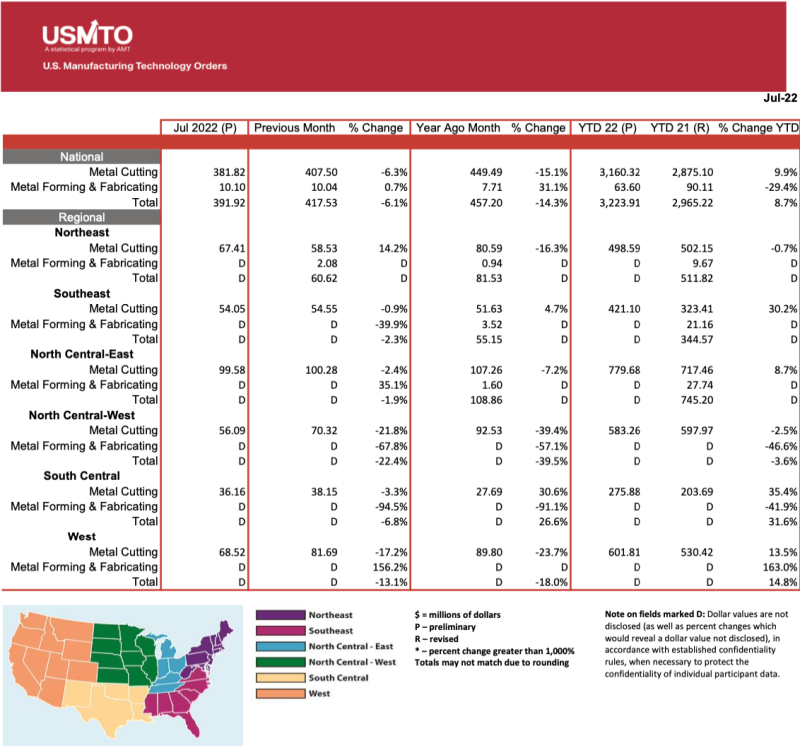

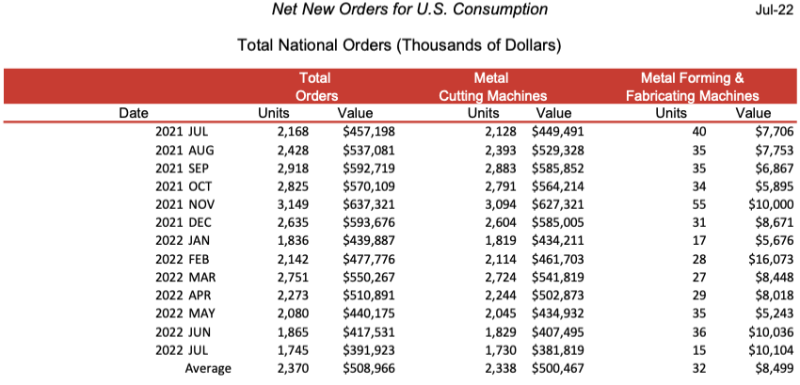

AMT’s latest U.S. Manufacturing Technology Orders (USMTO) report showed that July orders of metal cutting, forming and fabrication machines totaled $291.9 million, down 6.1% from June and down 14.3% year-over-year. Year-to-date orders through July totaled $3.22 billion, up 8.7% over the first seven months of 2021.

It followed a June in which orders were down 5% from May and down 16% year-over-year, and the July year-to-date total saw its year-over-year increase shrink from 13% advantage it had in June.

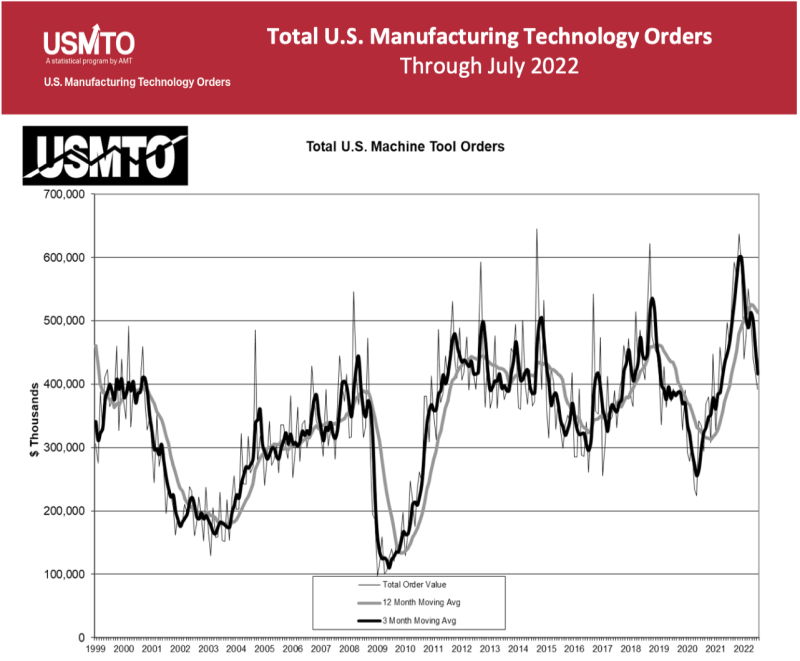

“While July 2022 is down compared to July 2021, orders in both years were quite above what would be seen in a typical year,” said Douglas Woods, president of AMT. “Last year was the best on record and was particularly fueled by strong orders in the last third of the year, so it will be hard to match. However, given that orders are already nearly 9% over 2021, and with the typical boost to orders from IMTS, it appears possible to come close.”

The transportation sector is typically a driver of manufacturing technology orders, but it led the retreat in July. AMT noted that orders placed by most motor vehicle manufacturing industries pulled back significantly in July after an outsized June order, while machine orders for railroad, ship and other transportation manufacturing also decreased. Within transportation, the one bright spot was in aerospace, led by space and defense sectors, where orders nearly doubled from June to July 2021.

AMT noted that manufacturing technology orders have significantly benefitted in the past two years from foreign direct investment, particularly in the production of semiconductors and batteries.

“Not only has foreign direct investment in the United States benefited manufacturing in recent months, but the trend of reshoring has also greatly increased the need for additional capacity,” Woods said. “Metal valve manufacturers, whom we have highlighted in previous months, continue to place orders for machinery at levels that would be unheard of just a few years ago.

“The ongoing desire to create more resilient supply chains will continue to require more parts to be made domestically,” Woods added. “That demand has pushed manufacturing capacity utilization to an over two-decade high. If these trends continue, it could create a sustained need for additional manufacturing technologies — and particularly automation, should manufacturers continue to grapple with a shortage of labor.”

See AMT’s July charts for manufacturing technology orders below:

Related Posts

-

Automotive powered much of the gain, which was a strong rebound after declines in June…

-

Average annual sales growth by participants had been in the 24-25% range since January.

-

A month-to-month acceleration in daily sales bodes well for fellow industrial distributors large and small.